- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

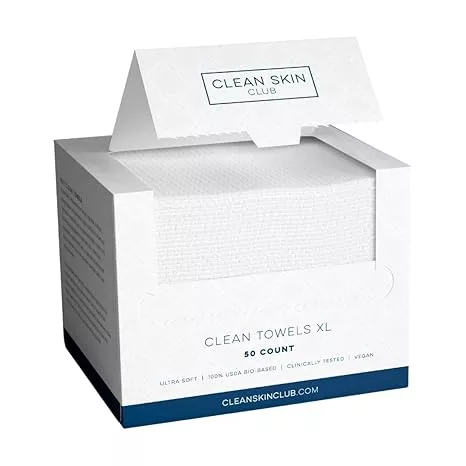

Disposable Towels for Body

TYMUS Disposable Towels for Body is made of exclusive Mixbond® lignin-spun nonwoven fabric with customizable fiber ratios to achieve ultra-fluffy texture and 3X water absorbency. Deeply customizable in thickness, size, and degradation cycle, providing one-stop service from R&D to global delivery.

Send Inquiry

Product Description

From sweaty moments at the gym to gentle post-operative care for sensitive skin, TYMUS Disposable Towels for Body are rewriting the standard for disposable cleaning products. Based on patented Mixbond® Lignin Spinning Technology, the product achieves a three-dimensional cross-linked structure of natural wood fibers and eco-friendly binders to achieve a level of fluffiness and water-locking ability unmatched by traditional materials. The chemical-free bleaching process preserves the natural color of the wood, making it safe to use even for fragile skin. Suitable for post-exercise sweat adsorption, medical care disinfection, SPA essential oil wipe and other scenarios, so that every touch becomes a commitment to quality.

Materials and Features

Mixbond® exclusive technology:

Super fluffy structure: 65% higher fiber porosity, adjustable thickness (1.5-4.0mm), touch feeling comparable to premium cotton towels.

Intelligent Water Absorption: Water absorption per unit area up to 800ml/m² (3 times that of ordinary non-woven fabrics), locking water without reverse osmosis.

Controllable environmental protection: the proportion of lignin fiber supports 30%-70% flexible adjustment, and the degradation cycle is adapted to the customer's regional policy (30-180 days).

Functional design:

Natural antibacterial: Lignin fiber inhibits the growth rate of E. coli bacteria up to 99.5% (SGS test), reducing the risk of cross-infection.

Dual-side texture: velvet surface (ultimate skin-friendly) or micro-frosted surface (gentle exfoliation), free to choose by scene.

Sustainable Commitment:

Zero wastewater discharge throughout the production process, with a carbon footprint 45% lower than traditional processes.

Support C2M reverse customization, matching absorbency, degradation cycle and cost budget according to customer needs.

Product Customization

Core technology customization:

Free combination of lignin fiber ratio (30%/50%/70%), thickness (1.5-4.0mm), grammage (50-120gsm).

Add functional layer: collagen moisturizing film, nano-silver antimicrobial coating, essential oil slow-release microspheres (lavender/eucalyptus).

Scenario-based packaging:

Rolled/folded/individual single piece, outer box printed with FSC certified recycled paper pulp + vegetable ink.

Theme design: sports energy style (fluorescent colors), medical minimalist style (blue and white stripes), SPA healing style (earth colors).

Flexible cooperation: MOQ starting from 1500 pieces, 7-10 days delivery cycle, support small batch trial production + rapid iteration.

One-stop service

Technical Empowerment: Free Mixbond® fiber ratio simulation system to visualize the effect of water absorption and degradation cycle.

Global Compliance: Assist in completing FDA, EU Ecolabel, China Degradation Standard and other certifications to avoid trade risks.

Intelligent logistics: DDP terms cover RCEP member countries, providing regional bonded warehouses for stocking and emergency expedited channels.

After-sales closed loop: 48 hours technical response, provide degradation data tracking report and customer experience optimization solutions.